Expert Flex Solutions

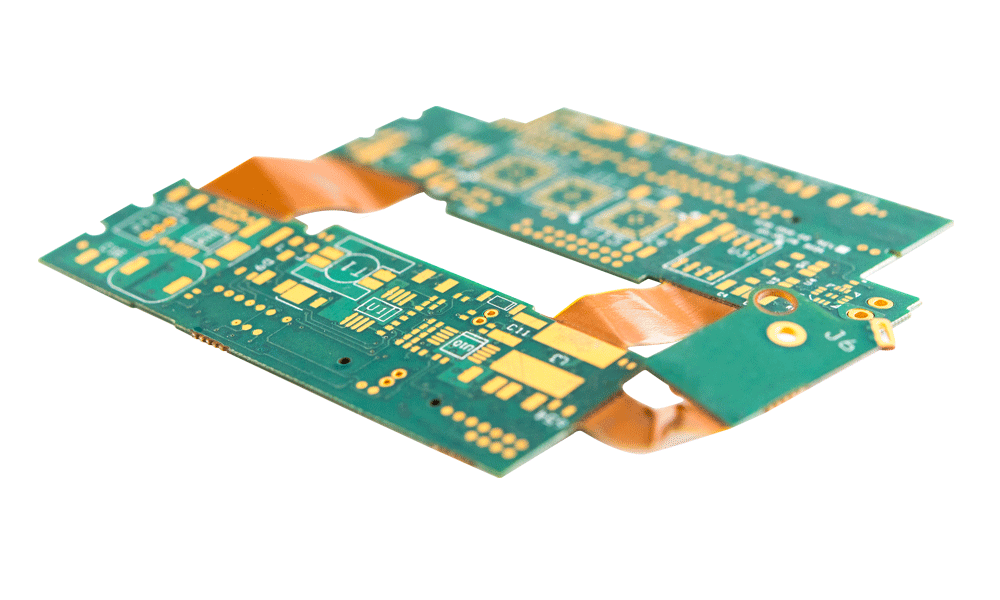

PFC offers turnkey solutions for challenging flex circuit design, manufacturing, and assembly. From development of bare flexible circuits, to full assemblies, PFC has the advanced capabilities to serve leading technology providers. Driven by years of experience, our highly skilled team delivers full turnkey services to help clients achieve a competitive advantage.

Flex

PFC offers turnkey solutions for challenging flex circuit design, manufacturing, and assembly. From development of bare flexible circuits, to full assemblies, PFC has the advanced capabilities to serve leading technology providers. Driven by years of experience, our highly skilled team delivers full turnkey services to help clients achieve a competitive advantage.

- Single-sided, double-sided, multilayer, and rigid-flex up to 16 layers

- High Speed, low loss, and impedance controlled solutions

- Fine line to 50 microns in production

- VIAs- Blind, stacked, buried, filled, via in pad

- Materials- as thin as 9 micron copper

- Various UL and shielding materials

- Heater flex and sculptured flex

Assembly

With two complete SMT lines in-house, PFC is able to assemble the flex we manufacture, thereby providing a complete solution for our customers. Whether it’s consigned components or a full turnkey solution, let PFC manage your assembly requirements. PFC offers lower cost assembly solutions at our facilities in Southeast Asia and can manage your product throughout its life cycle wherever is best to meet your needs.

- 2 high speed SMT lines up to 50,000 /hour

- Component placement to 01005

- BGA placement down to .35mm pitch

- High volume camera and LED placement

- Full functional testing, X-ray inspection

- MRP inventory management

- Turnkey or consigned components

- Conformal Coating

Certifications

- ISO 9001-2015

- ISO 13485-2016

Design Support

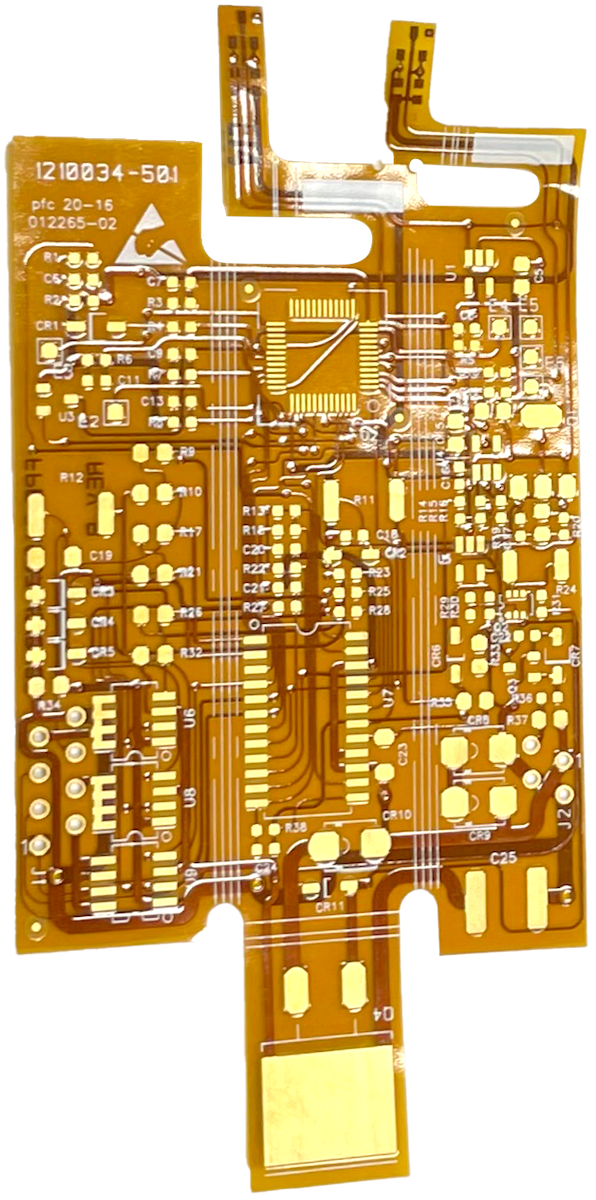

Flex Circuit Design

PFC designs flex circuits for thinner, lighter, and smaller technology using a special set of requirements unique to flexible circuitry. Understanding how these requirements interact allows us to create flex circuits that balance the electrical and mechanical features into a reliable, cost-effective interconnected solution. We deliver dynamic products that ultimately enable clients to reduce material and labor costs, and limit the number of complex connections in a design.

Design Innovations

Our industry leading DFM technologies and techniques translate to added value for customers. We use sophisticated equipment to create layout documentation and produce flex circuits. As a turnkey flex design, manufacturing, and assembly provider, we understand the critical design rules applicable to client needs. PFC specializes in building high-quality, robust flexible circuits based on specification and application.

Flex Circuit Development

PFC delivers full turnkey flexible circuit development. Our experienced team evaluates customer processes and products to provide insight on flex circuit efficiency. PFC’s early customer engagement process will develop the best design and engineering solutions.

- Component identification

- Material selection

- Process analysis

- Documentation

- Bend ratios

- Mechanical requirements

- Signal integrity

- Plating

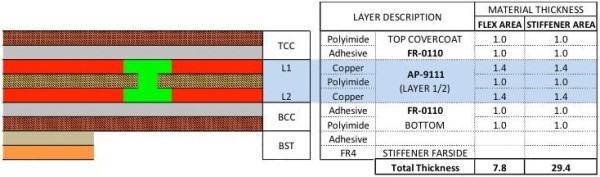

Material Selection

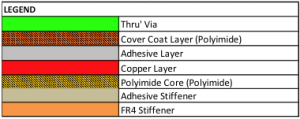

After a thorough discussion regarding your application, PFC will provide a list of specific materials and thicknesses that will be used in the manufacturing of clients’ circuits. This will include required adhesives, stiffeners and any special drilling requirements such as blind and buried vias. Below is an example of a material stack-up.

Qualification, Troubleshooting, & Failure Analysis

Process qualification, troubleshooting and failure analysis are key services, which help clients understand their products. Our in-house, advanced analysis equipment offers customers an in-house flex development partner.

Assembly Service

Flex Manufacturing Experts

PFC provides leading companies with customized flex circuit solutions and unbeatable customer service. Our integrated technologies and processes provide our clients’ a range of advanced flex and rigid flex circuits. Our team’s high level of technical capability supports production and quick-turn manufacturing requirements. With all manufacturing processes under one roof, we have the ability to manufacture end- to- end flexible circuits.

Assembly Excellence

As a leader in materials conversion, fabrication, and component assemblage for flexible printed circuits, PFC offers unbeatable assembly solutions. PFC continues to transform the flexible electronics industry by providing full turn-key assembly services. Our industry leading techniques and skilled team provide integrated assembly solutions.

Migration of Production

Migration of production to low cost regions.

Troubleshooting & Failure Analysis

Process qualification, troubleshooting and failure analysis are key services, which help clients understand their products. Our in-house, advanced analysis equipment offers customers an in-house flex development partner.

Test & Tooling

We perform inspection and testing at incremental stages throughout the development process to ensure that products are of the highest quality. We offer flying probe, universal grid, dedicated test systems, and more. Our in-house test program generation and fixture manufacturing also assures excellence. PFC assures quality flex circuits through our rigorous testing.

- 100% netlist driven test processes

- Netlist formats: IPC D356, ODB++, CAD generated

- IPC 9252 class 1,2 and 3 testing

- Hipot testing: dielectric breakdown, dielectric withstanding, insulation resistance

- Impedance testing

- In-house test program generation and fixture manufacturing

- Test parameters

- Continuity > 0.1 Ohms

- Isolation